Features of commutator engines

A commutator motor is a type of motor that consists of a fixed part and a moving part. The fixed part is called a stator, and the movable part is called a rotor. commutator motors can be DC, AC, and universal, all three types are widely distributed on the market and are found in household electrical appliances, construction and industrial equipment, as well as in various vehicle components, such as: motors for stoves and air conditioners, motors for parking heaters and clutch actuators, four-wheel drive pumps, ABS systems, etc.

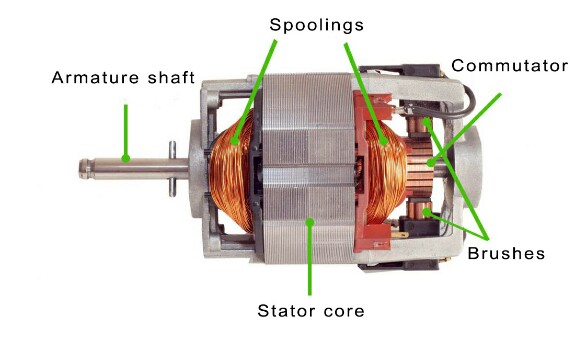

In automotive subjects, DC commutator motors are most common, they consist of the following parts: an armature, a copper commutator, a brush assembly, bearings and a fan.

The principle of operation of the engine is as follows: there are excitation windings in the stator, the rotor is responsible for transferring the resulting mechanical energy. A commutator is placed on the rotor shaft, with the help of which electrical energy is transmitted to the windings.

A commutator consists of copper bars, called lamellas, which are separated from each other by mica or textolite gaskets. Each lamella is attached with its ends to the rotor winding, and on the opposite side copper-graphite brushes fit snugly to the commutator, which creates good contact. The electricity supplied through the brushes to the commutator is transmitted to the rotor through the lamellas connected to it. The constant rotation of the rotor allows electricity to be transmitted to the entire surface of the winding.

Many customers complain that the commutators we sell sit and walk too freely on the rotor. This is absolutely normal, since, firstly, the commutator is fixed to the rotor winding, and secondly, even official motor manufacturers use various industrial adhesives to fix the commutator.

The advantages of using the above type of motors include: low cost, high rotation speed, simple design. Disadvantages are also present, among them: high wear of the brush assembly, brushes wear out, and they need to be changed regularly. If this is not done, the brush holder may melt, and it will need to be changed, which increases the cost of repairs. Also, the commutator itself wears out over time, and a rut forms on it, as a result of which the brushes no longer fit snugly, power is lost, the engine is unstable, or stops working altogether.

Our store offers a wide range of components for brush motors: copper-graphite brushes of different sizes, brush holders, commutators, bearings and rotors. All this you can purchase at a low price, and with delivery in Russia, near and far abroad.